Background

During the past two decades, irrigation loads have grown exponentially. Growth in Power generation has been slow as compared to the load thus there is a deficit of power.

As subsidized/Free power is supplied to Irrigation Pump(IPset) consumers the utilities would like to control consumption beyond normal limits. Moreover, IP sets can be scheduled to operate in a time of off-peak loading thereby rationalizing the overall load curve.

The traditional method of rostering has not yielded the desired result. The load shedding has caused an interruption of power supply to domestic lighting & rural commercial load. Due to this lot of revenue is lost which is not subsidised.

The distribution system is generally overloaded as the utility has no control over the IPset loads. Presently the consumer can switch on the IP set load at any desired time. These IPset have poor power factor performance leading to lower voltages and an increase of distribution loss at the supply points.

Using effective load management the utility would control the IP set consumption as per the desired time frame (Off peak hours), regular supply to the rural domestic and commercial consumers, ensure committed number of hour supply to IP loads.

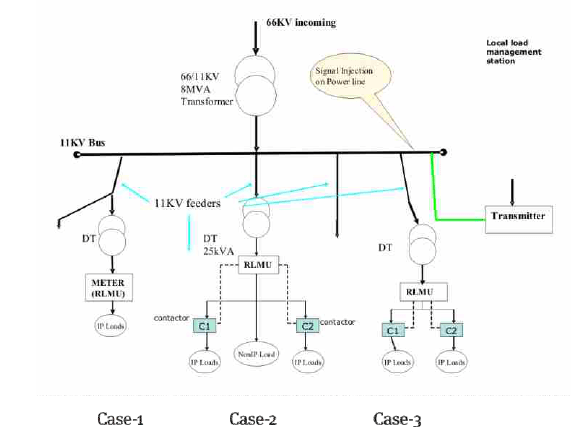

In order to implement a scheme of effective load management on the IP sets, the feeders for the IPset and the normal consumers are separated. On the IP set feeder, the Rural Load Management Unit (RLMU) is proposed to control the IP loads.

In this scheme, each Transformer is divided into different feeders for industrial, rural consumers, and IP consumers. Two different feeders are used for IP and one for rural commercial & domestic consumers. Complete IP load is divided into two parts and at a time only one feeder of IP load is switched ON whereas non-IP loads are given supply continuously.

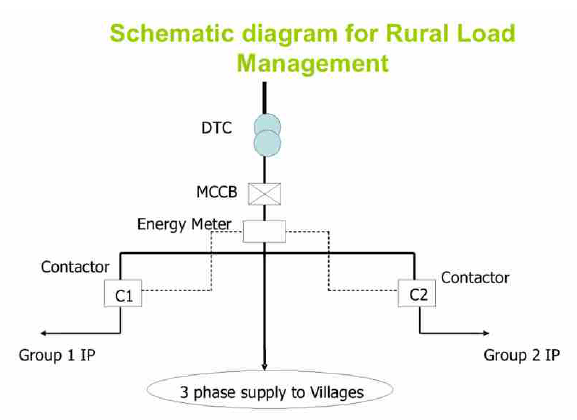

This means that at a time only 50% of IP load is switched ON. Our system works on full load most of the time and efficiency is increased. The contactor is used to switch on/off the IP load according to availability of power whereas the domestic consumers are provided with uninterrupted supply. It requires only negligible modification of the existing system. The schematic diagram of the scheme is shown below.

The schematic diagram of the scheme is shown below:

In this scheme there is only one IP load feeder which will be controlled by one RLMU unit which includes metering unit, receiver and load control switch. This will be used up to 100A

In this scheme, each transformer is divided into different feeders for Industrial, Rural consumers, and IP consumers. Two different feeders are used for IP and one for rural commercial & domestic consumers. Complete IP load is divided into two parts and at a time only one feeder of IP load is switched ON whereas non-IP loads are given supply continuously as no contactor is connected in non-IP load feeder. This means that at a time only 50% of IP load is switched ON. The proposed system works on full load most of the time and efficiency is increased.

The RLMU unit consists of the main unit and contractors enclosed in a tamper-proof box. The RLMU unit will individually control the two IP load feeders. The contactor is used to switch on/off the IP load according to availability of power whereas the domestic consumers are provided with uninterrupted supply.

In this scheme the complete IP load is splitted in two parts and committed number of hour supply is given to both the IP loads separately. Since non-IP load is not present in this case provision for continuous supply is not provided.

Main advantages of RLMS: