Introduction

Electricity Metering Over Multiple Feeders is a common problem faced by the electricity Supply Industries, Independent Power Producers. Railways and on Grids interconnecting two states. This paper reviews the need for Multiple Feeder Metering and the various approaches for the application along with their advantages and limitation.

This paper is written with an intention for sharing the fundamentals on summation metering and special attempt is made to appreciate the complexities associated with Multi-Feeder Metering in the reader friendly way.

Multiple feeder supply is preferred by the electricity supplier in the following two situations:

For electricity invoicing on bulk electricity consumers, it is the energy and demand that forms the input . Tariff metering becomes complex in case of multi-feeders due to the challenges poised by the measurement of summated energy and concurrent maximum demand over multiple feeders.

For better appreciation of the problem, let us consider a practical case of an industry having two feeders for the supply and the tariff is of two parts. The first part of the tariff comprises of the KVA maximum demand drawn by the consumer and the second part comprises of the kWh consumed by the consumer in the billing period. Let us assume that the contract demand of this consumer is 200 kVA. The inference of this contract demand from the suppliers prospective is, at no time, the consumer must draw more than the average of 200 kVA demand from the utility.

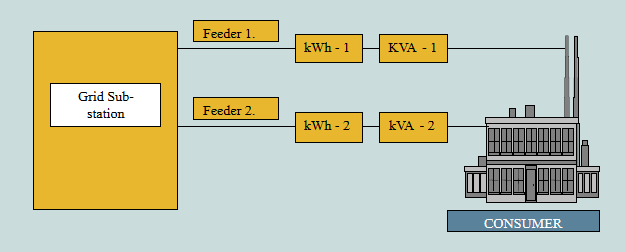

In the above figure, the consumer is receiving electricity over two feeders emerging from the same Grid Sub-station the reason for installing two feeder may be the increase in contract demand. The feeders are named as Feeder – 1 and Feeder – 2.

One energy meter and demand meter is installed on each feeder to measure the respective kWh consumption and recording the KVA maximum demand drawn over the respective feeder..

For computing the total kWh consumed over the two feeders, the arithmetic addition of the KWh – 1 and kWh -2 will serve the purpose. We summarize, that discrete kWh meters can be used on each feeder for arriving at the summated kWh of the consumer.

For computing the Summated KVA, adding the readings of the two KVA demand meters will be misguiding as both the maximum demand may not have occurred at the same time demand integration period time frame. It may be the case that the consumer might have drawn 200 kVA on FEEDER -1, keeping Feeder open and again he is free to draw 200 kVA over Feeder – 2, keeping Feeder – 1, open. Please note that he has not exceeded his contract demand which is 200 kVA. Adding the two feeders KVA demand as we have done for kWh, gives a total of 400 KVA, which is the wrong way to do. To summarize, the summated demand can not be derived by summing the readings of the KVA demand meters due to diversity of loading. The billing demand should be the concurrent maximum demand.

Concurrent demand is the demand measured on a single equivalent feeder of the multiple feeders in the same time domain.

The concurrent demand measurement :

To solve the problem of concurrent maximum demand, following methods are used:

Each of the above methods has been explained in depth in the following sessions along with their pros- cons and limitations.

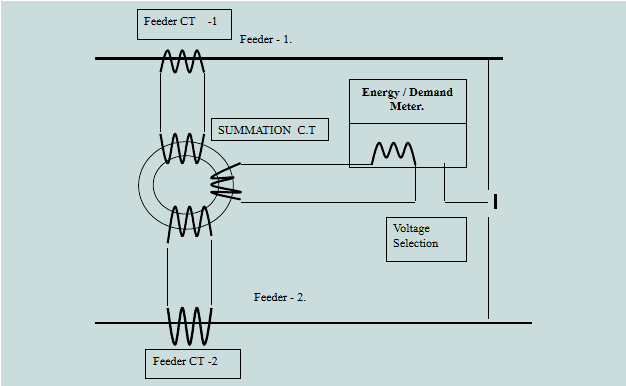

Summation CT is an interposing Current transformer which has n+1 winding, where n = number of feeders and the constant 1 is used for the single secondary winding.

Application: Summation CT

The Feeder CT’s have a typical output of 1 or 5 Amps, the secondary windings of the multiple feeders is connected to the multiple primaries of the Summation CT. The current signal available in the secondary winding will be the vector summation of the multiple feeders.

Summation CT’s have a typical rating like 1+1 / 1Amps OR 5 + 5 / 5 Amps, which means that such a CT is suitable for two feeders summation which has the measurement CT having the secondary rating of 1 Or 5 Amps respectively.

The output of the Summation CT is then connected to the Current Circuit of the Energy / Demand Meter and the reading so obtained is the Summation of energy and Demand.

Fig: Schematic diagram of a two-feeder Summation Metering using Summation C.T

The above diagram shows the Summation of two feeders 1 & 2, using a Summation C.T. The secondary of the Feeder CT of each feeder is connected to the Summation CT. The two feeder currents may have individual magnitude and phase, whereas the Summated output from the Summation C.T. will be the vector SUM of the two currents. This current is further fed to the Energy & Demand Meter having a single current coil per phase.

It is the commonly used three vector meter having one current and Voltage coil per phase. The current coil of the meter is connected to the output of the Summation CT; thereby it receives the SUMMATED current of the two feeders. The meter has a single

Voltage coil and can be connected to any of the feeder. A Voltage selector relay is provided to connect the Energy / Demand meter to the Feeder having Voltage in case one of the feeders becomes electrically dead.

The Summated C.T has two types of errors viz. the Phase Angle Error and the Ratio Error. Having Multiple wound primaries, a third type of error is introduced in the system caused by the circulation current in the Feeder C.T. circuit which is lightly loaded.

When the two load currents are applied on the SUMMATION C.T. respective fluxes are established in its core. The two primary fluxes adds up as per the law of vector addition resulting to the total primary flux which is also linked with the secondary winding of the summation C.T. Due to transformer action, a proportional secondary current is produced in the closed circuited secondary flowing through the energy meter. The current seen by the meter is the vector summation of the two currents.

As the Summation of the two feeder current is carried out instantaneously, the Ideal Summation C.T. may be called as the ideal technical solution to summation metering. In real life, the case is not so, Summation C.T. has a list of errors which forces the metering engineers to study it as a principle but skeptic to use for SUMMATION METERING is needed on bulk power transfer feeders which has a highest commercial stake to venture with.

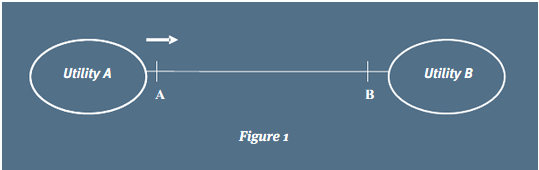

Over a tie-line, the power flow may be BI-lateral. Here we going to discuss the performance of the summation C.T. on a tie-line comprising of two feeders F1 and F2 connected between the power pool A&B. We will discuss the following combinations:

SUMMATION C.T. has the following Limitations:

In past, summation CT’s were used, but resulted to numerous errors and restrictions. It also caused lots of dispute and the total measurement error in tune of 7% have been reported in certain installations.

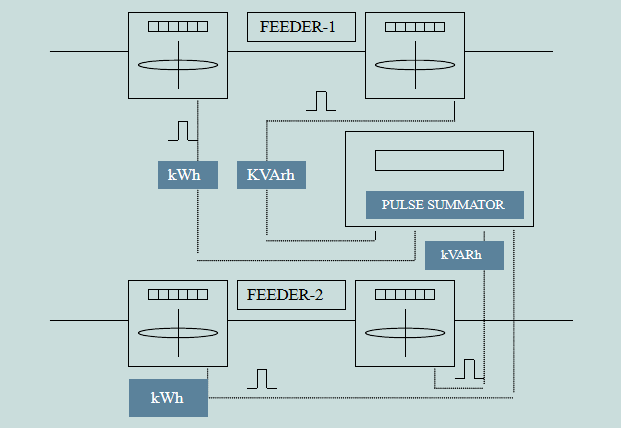

The underlying principle using Pulse summation is to get rid of the “time domain” in the measurement and summing the feeder energy instead of currents. Each feeder has its dedicated kWh and KVArh meters which has a provision for pulse generation for each unit / sub-unit of the quantity measured. There is PULSE SUMMATION UNIT which receives all such KWh and KVArh pulses from various feeders. This PULSE SUMMATION unit adds up the kWh and KVArh pulses to arrive at the total kWh and KVArh. The pulse summation unit has time clock to further compute the KVAh and KVA maximum demand.

The advance versions of the Pulse Summation Units has the facility for multiplying the pulses with the pulse weight to arrive at the true energy flow in terms of the feeder primary quantities.

These are special kWh / KVArh meters which have a Volt-free contact which is actuated by the disc revolution. Being Electro-mechanical in construction, the maximum pulsing frequency can not be more than 2-4Hz. This frequency limitation of the contact imposes a limitation on the resolution factor defined by Pulses/kWh or Pulses/KVArh. For a 220KV, 400 Amps feeder having a 3Hz pulse frequency meter, the maximum pulses/kWh will be around 30 kWh / pulse (taking full scale as 200% of 400Amps). This numerical demonstrates the consequence of loss a pre-mature pulse which may result to a measurement error of 30 kWh. The errors will be profound in case of KVAh and kVA demand computation as kWh and kVArh meter may have the same limitation.

The pulse type of Summator has the following limitations:

This system has overcome all the disadvantage of the pulse and C.T based summation system by using a single, true four quadrant, electronic meter on each of the feeders with the facility for electronic communication with the Digital Summator.

The meter measures electricity in the resolution of 0.01 kWh / kAVrh and records the increments in its registers. The digital summation device reads this register for acquiring the energy increments. Thus even the minutest increment (as low as 0.01) can be detected by the digital summation and accounted for it. If we compare the digital summation with the pulse based summation of the highest resolution (3Hz) the digital summation is 30kWh/0.01kWh or 3000 times more accurate.

The digital Summator has a micro-processor which sequentially reads (polls) the electronic feeder meters over the communication channel to collect the kWh(import/ export) and kVArh(lag / lead) increments. The energy increment is in digital format has a very high resolution which may even extent upto a watt-hour or its fraction. The accuracy of such a system depends upon the following parameters:

The digital summation device then adds up the “likes” , e.g. adds the kWh (imports), kWh (Exports), kVArh-lagging / leading and further computes the demand based on the summation.

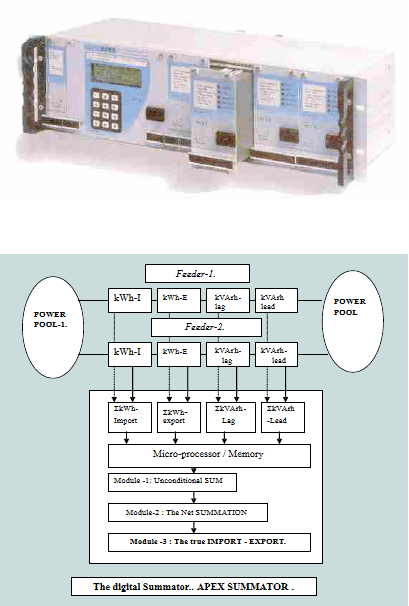

To understand the operating principle and the various other features of the digital Summation, the summation meters from M/s Secure meters Limited having the brand name “APEX SUMMATOR” is discussed. It is worth mentioning that SECURE METERS LIMITED is the only manufacturer in the country for digital Summation systems.

Before we enter into serious examinations of the digital summator, we review some of the practical field situations which makes the Summation metering more complex. Those conditions are as:

Number of feeders : Mostly, the number of feeders in a typical consumer installation are two, however, for power plants (IPP’s) and inter-state metering the number of feeders may be upto six. Such a measurement requirement calls for a Summation Metering Scheme for six to eight feeders.

Feeder Voltages : The Feeder connecting the two power pools may have different origins and terminations, hence they may have different operating voltages. For example, the IPP may be connected to the 400 KV national grid, 220KV or 132 KV state grid and to 132 KV load center, the custodian for revenue settlements may be the state electricity board. This requirement calls for the metering system to operate at different feeder Voltages. Please note that in such a situation, the Summation C.T and Pulse Summator can not be used.

Loop Line Flow : In situations where the two power pools are connected by feeders having different origins or such a network conditions where the energy flows in a few of the feeders in the import direction and returns back in the remaining feeder(s). This phenomenon is called as loop line flow. The challenge in such a situation is to measure only the energy consumed by the consumer and over-looking the phenomenon of loop-line flow. This problem

call for the Summation meter to measure the NET energy and demand. It is also worth mentioning that the loop line flow may be observed in case reactive energy, a typical example may be MVAR-Lag on one feeder may be 200, whereas at the same time on the other Feeder it may be 80 MVAR-leading. Thus the consumer is only using 200-80 = 120 MVAR-lagging at that instant.

Apex Summator is the summation metering system from Secure meters Limited, which is capable of performing tariff metering over multiple feeders. It comprises of the following elements:

The typical accuracy of the feeder meters is class 0.2S and is available in 1/ 5 Amps of basic current. The Feeder Meters has a local display wherein all the energy demand, Time Of Use transactions of the specific feeders can be obtained. The Feeder Meter also has the facility for load curve recording and the number of channels may be up to four. The data from the feeder meter can be downloaded electronically through the conventional meter reading port. As the SUMMATION metering is employed for bulk

power transfer, the supplier and the receiver have a concern over the integrity of metering, hence the feeder meter is equipped with the advance tamper detection hardware supported by the proprietary tamper detection algorithm of Secure meters Limited. Furthermore, Feeder Meters are based on the same CALMU® technology which has proven itself for its reliability and accuracy in the hostile Indian electrical and environmental conditions by nearly all the Electricity Boards and Utilities for over a decade.

Apex Summator uses fast sequential communication with various feeder meters for the four-quadrant energy increment acquisition. The captured data is processed by using microprocessor(s) modules to finally arrive at the following tariff needed results:

Operation: The Apex Summator interrogates with the feeder meters and collects the incremental energy data, which is in very high resolution. These data are processed to obtain various tariff-related quantities.

The APEX SUMMATOR is made up of discrete modules like the True import-export module which finds applications in tie-lines connecting Electricity Boards to the IPP’s, it has the NET module which is deployed in networks where there is a possibility of LOOP-LINE-FLOW. Besides these features, there are needs for performing the metering based on special conditions like the active energy may be computed on NET basis, whereas for the reactive energy, the unconditional metering may apply. APEX SUMMATOR can be factory configured for such selective metering also.

In case of IPP metering, the rule of the game is totally different and is governed by the Power Purchase Agreement (PPA). Every IPP have their own PPA and which in turn calls for a dedicated metering system. APEX SUMMATOR and APEX ( a new breed of precision meters from Polymeters Response International) can be programmed for to take care the various clauses of the PPA and to make

a metering system tailored for the particular application. For example, these meters can measure the availability factor, deemed generation and other jargons which forms an important part of the PPA. APEX, has a unique feature of a built-in PLCC / PSTN modem which continuously transfers the energy transactions to the Electricity Boards Grid

Sub-station / Load Dispatch center for the on-line demand-supply negotiations.

The key features of APEX SUMMATOR are as follows:

Summation metering is done for revenue intensive points and hence the designer should take into consideration all the possible combinations which may come on the way. For the benefit of the metering /commercial engineer a check-list has been developed which may be of help while selecting and specifying a metering scheme:

The Single line diagram:

The detailed SLD for the two parties should be available with stress on the Various feeder Voltages, the origination and sink of each feeder should be known and understood. If a generator is connected on either -end, the possible combinations of its power flow should be worked out. All the circuit combinations obtained by the switching in/out of the circuit breakers should be made clear. One should check for the connections of the power transformers and if they are in star connection, the three element feeder meters should be invariably used.

The Tariff structure:

Basically a metering scheme is meant for revenue and before deciding on the metering scheme, the tariff structure needs to made clear and a mutual consent between the two parties should be established. The tariff must be debated over the following lines:

Active energy: kWh

Re-active energy: kVArh

1. The checklist for active energy must be referred to, the only difference here is the treatment of the Reactive lagging and leading energies.

Apparent Energy:

Apparent energy is a derived quantity , it is composed of the kWh and kVArh which is added as per the rules of the vector mathematics. The following points needs to be checked for ascertaining the metrology for apparent energy computation:

Demand charges:

In case of IPP’s, there are some special clauses which are arrived after mutual consent and is available in the PPA between the parties. These clauses may or may not be common. The modern summation metering equipment can accommodate these clauses and can be enforced by receiving the authenticated signature and message from the utility over the telephone lines.

Conclusion

More and more metering nodes are coming up where multi-feeder summation metering is needed. With the coming up of the IPP’s on the grid, the metering and commercial engineers will be getting more exposure on the topic. This article was meant to provide the fundamentals behind the summation metering, the developments which have taken place and the new capabilities of the digital summation meters.